John Deere Sprayer Parts and Attachments

|

|||

Express™ Nozzle Body End Caps |

|||

|

Express Nozzle Body End Caps include a passive feature that eliminates trapped air. By allowing air to escape through the nozzle body, it reduces nozzle turn-off/turn-on times by 85 percent. With its removable end plug, it's easy to fush debris from the boom pipe, making boom cleanout a breeze. |

|||

|

Part Number | Description | |

| PM74333316 | 1 in. Express Cap Fitting w/ Nozzle Body End Cap (standard) | ||

| PM74333314 | 1 in. Express Cap Fitting w/ Nozzle Body End Cap (high fow) | ||

Express™ Wet Boom Fittings |

|||

| Express Wet Boom Fittings feature a connection that is quick and easy to assemble, while providing a quality, leakproof seal for stainless steel or polypropylene pipe. | |||

|

Part Number | Description | |

| Universal Flange Wet Boom Fittings | |||

| PM74332502 | Express Cap Fitting X 1 in. Universal Flange Straight | ||

| PM74332503 | 2 Express Cap Fittings X 1 in. Universal Flange Tee | ||

| Hose Barb Wet Boom Fittings | |||

| PM74332608 | Express Cap Fitting X 1 in. Hose Barb Straight | ||

| PM74332610 | Express Cap Fitting X 1 in. Hose Barb Elbow | ||

| Cam Lock Wet Boom Fitting | |||

| PM74332613 | Express Cap Fitting X 1 in. Male Cam Lock Straight | ||

John Deere Nozzle Bodies |

|||

| Changing nozzles can be a time-consuming, tedious task. But with our two turret styles, 3-way and 5-way, you get the most effcient change of spray tips possible. Simply rotate the nozzle body until the desired nozzle is in the spraying position. ■ Our nozzle bodies have the highest fow rates in the industry across the spraying pressure range ■ And they provide the lowest pressure drop at any given fow in the industry. |

|||

|

Part Number | Description | |

| High-Flow Nozzle Bodies | |||

| AN206621 | 5-position, 11/16-in. port, Viton seals | ||

| PMHF12DCVV | 12-psi check valve with Viton (16 open/12 close) | ||

| PMHF15DCVV | 15-psi check valve with Viton (22 open/15 close) | ||

| 3-& 5-way Nozzle Bodies with Tab for Boom Clamp | |||

| PM42W7 | 3-position, 1/2-in. clamp | ||

| PM42Y7 | 3-position, 3/4-in. clamp | ||

| PM42K7 | 3-position, 1-in. clamp | ||

| PM49Y7 | 5-position, 3/4-in. clamp | ||

| PM49K7 | 5-position, 1-in. clamp | ||

| 3- and 5-way Nozzle Bodies for Wet Boom (no tab for Boom Clamp) | |||

| AN206179 | 3-position, 3/4-in. pipe size | ||

| AN305431 | 3-position, 1-in. pipe size | ||

| AN305432 | 5-position, 1-in. pipe size | ||

| Single Drop Nozzle Body for Wet Boom | |||

| PM745 | for 1/2-in. pipe size | ||

| PM755 | for 3/4-in. pipe size | ||

| PM765 | for 1-in. pipe size | ||

Push-to-Connect Nozzle Bodies and Caps |

|||

| Push-to-Connect nozzle bodies and caps are commonly used in starter fertilizer applications. Nozzle bodies are available with push-to-connect by push-toconnector or push-to-connect by bayonet for use with either 1/4 in. or 3/8 in. OD, linear, low-density polyethylene tubing. Utilize the push-to-connect caps with a fow-regulating disc for precision metering at the nozzle. |

|||

|

Number | Description | |

| Push-to-Connect Caps | |||

| PM42000060 | Push-to-Connect (PTC), 1/4 in. Cap w/ gasket | ||

| PM42000061 | Push-to-Connect (PTC), 3/8 in. Cap w/ gasket | ||

| Push-to-Connect Nozzle Bodies | |||

| PM4247NB119 | Push-to-Connect (PTC) to Bayonet, 1/4 in. nozzle body, 4 PSI | ||

| PM4247NB129 | Push-to-Connect (PTC) to Bayonet, 1/4 in. nozzle body, 8 PSI | ||

| PM4247NB111 | Push-to-Connect (PTC) to Bayonet, 3/8 in. nozzle body, 4 PSI | ||

| PM4247NB121 | Push-to-Connect (PTC) to Bayonet, 3/8 in. nozzle body, 8 PSI | ||

| PM4247NC119 | Push-to-Connect (PTC) to PTC, 1/4 in. nozzle body, 4 PSI | ||

| PM4247NC129 | Push-to-Connect (PTC) to PTC, 1/4 in. nozzle body, 8 PSI | ||

| PM4247NC111 | Push-to-Connect (PTC) to PTC, 3/8 in. nozzle body, 4 PSI | ||

| PM4247NC121 | Push-to-Connect (PTC) to PTC, 3/8 in. nozzle body, 8 PSI | ||

|

|

|

|||

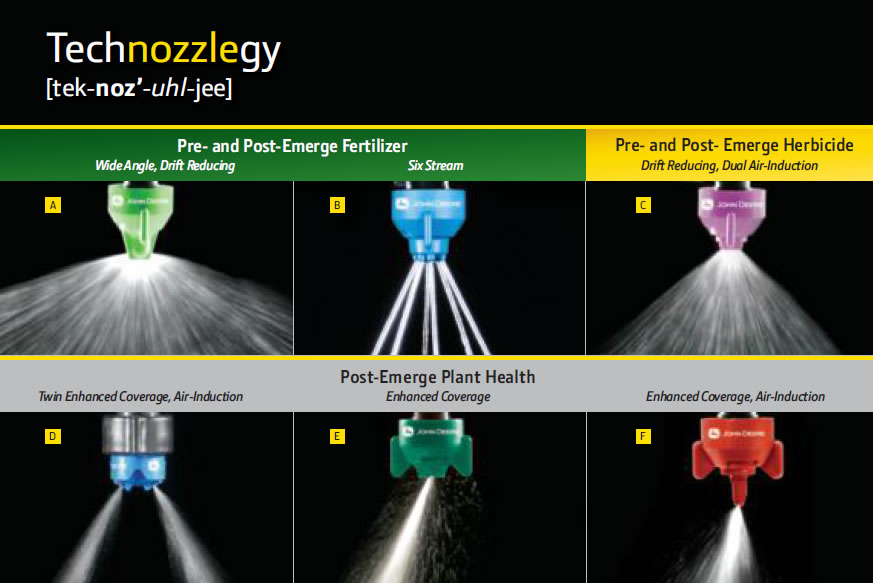

Technozzlegy: Targeted spraying yields greater plant health |

|||

| John Deere is redefning sprayer performance and accuracy with a concept so advanced we’re calling it Technozzlegy. Nozzles, engineered for pinpoint accuracy, reach the exact part of the plant you’re aiming at for every application: fertilizer, herbicide, fungicide, and insecticide. Ask for details on how to increase plant health with Technozzlegy today. | |||

| A | High Flow for pre- and post-emerge fertilizer ■ Wide-angle, 140-degree pattern allows for low boom height, minimizing corrosive effects on application equipment ■ Tapered, wide-angle fan style promotes uniform nutrient application |

GuardianAIR Twin™ for fungicides and herbicides ■ Ideal for high-coverage applications where plant management is critical ■ Forward- and rear-facing fans help penetrate dense canopies ■ Easy-to-install, patent-pending locking ring and O-ring seal design ■ Perfect for low crops with complex canopies such as small/cereal grains and soybeans |

D |

| B | Straight Stream Ceramic for fertilizer ■ Optimized solution for applying fertilizer into solid-seeded crops such as timed nutrient application ■ Provides a six-stream pattern so foliar contact is minimized and uniform coverage ensured ■ Ceramic metering orifce and low-pressure distribution chamber keep the streams stable. This reduces atomization and prevents leaf burn, making it ideal for top-dress use |

Guardian™ for fungicides and insecticides ■ Complete versatility when targeting weeds, fungus, and insects—even when using adjuvants ■ Bold arrow indicates incline direction for easy installation ■ Re-engineered for today’s high-speed application equipment |

E |

| C | Ultra Low-drift for herbicides ■ Ideal for applying pre- and post-emergence herbicide applications, where drift reduction is paramount ■ Small, compact size reduces the chances of accidental breakage ■ Wide-angle, 120-degree and thick, 60-degree spray pattern enables boom height to be lowered to further decrease drift potential |

Low-drift Air for fungicides and insecticides ■ Air-induced droplets reduce drift while increasing deposition and retention on foliage ■ Provides better coverage with more drops per gallon/liter compared to other, common, air induced spray tips ■ Speed-optimized spray incline allows more uniform coverage |

F |

High Flow |

|||

| Application: Liquid Fertilizer | |||

|

High Flow |

gpm |

HF 140 deg. – ASABE droplet classification chart |

Quick change |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

20 psi |

30 psi |

40 psi |

50 psi |

60 psi |

70 psi |

80 psi |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

0.80 |

UC |

UC |

UC |

UC |

XC |

XC |

XC |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

1.00 |

UC |

UC |

UC |

UC |

XC |

XC |

XC |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

1.50 |

UC |

UC |

UC |

UC |

XC |

XC |

XC |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

2.00 |

UC |

UC |

UC |

UC |

XC |

XC |

XC |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

3.00 |

UC |

UC |

UC |

UC |

XC |

XC |

XC |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

4.00 |

UC |

UC |

UC |

UC |

XC |

XC |

XC |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

5.00 |

UC |

UC |

UC |

UC |

XC |

XC |

XC |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

6.00 |

UC |

UC |

UC |

UC |

XC |

XC |

XC |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Straight Stream Ceramic |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APPLICATION: Liquid fertilizer | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ultra Low-drift |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APPLICATION: Herbicide chemicals | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

GuardianAir Twin™ |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APPLICATION: Insecticides/fungicides in dense canopies | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Guardian™ |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APPLICATION: Insecticides/fungicides | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Low-drift air |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APPLICATION: Insecticides/fungicides | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cast-Iron Centrifugal Pumps |

||||

| Pressures up to 180 psi ■ Cast iron for durability ■ Primarily for self-propelled and high-performance sprayers |

||||

|

NUMBER |

DESCRIPTION |

|||

|

4-12 gpm, centrifugal, hydraulic drive |

|||

| PM9302CHM1C | 11 gpm, hydraulic motor driven, 11/4 in. x 1 in. | |||

| PM9303CHM4C | 7 gpm, hydraulic motor driven, 11/2 in. x 11/4 in. | |||

| PM9303CHM1C | 10 gpm, hydraulic motor driven, 11/2 in. x 11/4 in. | |||

| PM9304CHM1C | 10 gpm, hydraulic motor driven, 2 in. x 11/2 in. | |||

| PM9304CHM5C | 15 gpm, hydraulic motor driven, 2 in. x 11/2 in. | |||

| PM9006CO | 540 rpm, PTO mount, gear driven | |||

| PM9016CO | 540 rpm, solid shaft, gear driven | |||

| PM9008CO | 1,000 rpm, PTO mount, gear driven, 21 spline | |||

| PM9203C | Cast, pedestal mount, 11/2 in. x 11/4 in. | |||

| PM9203CR | Cast, pedestal, reverse rotation, 11/2 in. x 11/4 in. | |||

| PM9303CH1CBU | 11 gpm, hydraulic motor driven, 11/2 in. x 11/2 in., universal fange | |||

| PM9306CH1CBU | 11 gpm, hydraulic motor driven, 2 in. x 11/2 in., universal fange |

|||

| PM9306CH5CBU | 15 gpm, hydraulic motor driven, 2 in. x 11/2 in., universal fange |

|||

Stainless Steel Centrifugal Pumps |

||||

| Pressures up to 170 psi ■ Stainless steel for maximum wear ■ For skid-mount or self-propelled sprayers |

||||

|

NUMBER |

DESCRIPTION |

|||

|

PM206042S | Stainless steel, 18 gpm, hydraulic driven, centrifugal pump – 2 in. x 11/2 in. Direct replacement for aN206042 | ||

| PM303707S | Stainless steel, 14 gpm, hydraulic driven, centrifugual pump – 11/2 in. x 11/4 in. Direct replacement for aN303707 | |||

| PM9203S | Stainless steel, pedestal-mount centrifugal pump –11/2 in. x 11/4 in. | |||

| PM9303SHM1C | Stainless steel, 13 gpm, hydraulic driven, centrifugal pump – 11/2 in. x 11/4 in. | |||

| PM9306SHM5C | Stainless steel, 17 gpm, hydraulic driven, centrifugal pump –2 in. x 11/2 in. | |||

Silicon-Carbide Seal Kit |

||||

| ■ More resistant to abrasion than ceramic ■ More likely to survive dry runs than ceramic ■ Silicon-carbide seal faces work together to provide excellent thermal conductivity for dry running ■ Pressure-balanced design allows for lighter spring loads, lower running temperatures and longer seal life |

||||

|

NUMBER |

DESCRIPTION |

|||

| AN206043 | Silicon-carbide seal kit | |||

|

||||

Load Command™ System |

||||

| Load 1,200 U.S. gal in as little as three minutes. With this fully integrated solution, designed specifcally for the 4930 and 4940 Self-Propelled Sprayers, you can get back to the feld faster and spray more acres per day. | ||||

|

NUMBER | DESCRIPTION | MODEL | |

| BKK10117 | Machines with Eductor | 4940 | ||

| BKK10118 | Machines without Eductor | 4940 | ||

| BKK10171 | Machines with Eductor | R4045 | ||

| BKK10107 | Machines without Eductor | R4045 | ||

| BN909651 | Tender Arm and Mounting Structure | 4940 and R4045 | ||

| BN202580 | Tender Arm Bundle | 4940 and R4045 | ||

Boom Cleanout Kit |

||||

| Simply mount this kit on the ends of each boom section, then open to fush the system and avoid any clogging. Use with 1-in. plumbing. | ||||

|

NUMBER |

APPLICATION |

||

| BN202517 | 4630 - s/n 0000-28001 | |||

| BN202517 | 4700, 4710, 4720, 4730, 4830, 4920, 4930, and 4940 | |||

BoomTrac Pro™ Height Control System |

||||

| A proven way to dramatically reduce spray drift and skips. This system increases application accuracy and effciency by maintaining a more consistent boom height above the crop. | ||||

| NUMBER | DESCRIPTION | MODEL | ||

|

BN909714 | 3-Sensors (s/n 0000-8316) | 4630 | |

| BN400195 | 3 Sensors (s/n 13001- up) | 4630 | ||

| BN909614 | 5-Sensor System | 4730 and 4830 | ||

| BN202556 | 3-Sensor System | 4730 and 4830 | ||

| BN202557 | 2 Additional Sensors | 4730 and 4830 | ||

| BKK10019 | 5-Sensor System | R4030, R4038, and R4045 | ||

| BN202539 | 3-Sensor System | 4920 | ||

| BN909563 | 5-Sensor System | 4920 | ||

| BN909527 | 5-Sensor System | 4930 and 4940 | ||

| BN202519 | 3-Sensor System | 4930 and 4940 | ||

| BN202520 | 2 Additional Sensors | 4930 and 4940 | ||

Underframe Shields |

||||

| Simply mount these shields to the underside of the chassis to help protect your crop from entanglement in vehicle components. Shields are mounted on hinges to allow quick, easy access to vehicle components. Fits most model year sprayers. Available for John Deere Sprayer models 4630, 4730, 4830, 4930, and 4940. | ||||

|

NUMBER |

APPLICATION |

||

| BN202606 | 4630 | |||

| BN202453 | (s/n 4939 and below) and 4830 (s/n 3382 and below) | |||

| BN202593 | 4730 (s/n 4940-8000) and 4830 (s/n 3383-8000) | |||

| BN202613 | 4730 and 4830 (s/n 8001 and up) | |||

| BN400415 | 4940 | |||

| BKK10017 | R4030, R4038, and R4045 | |||